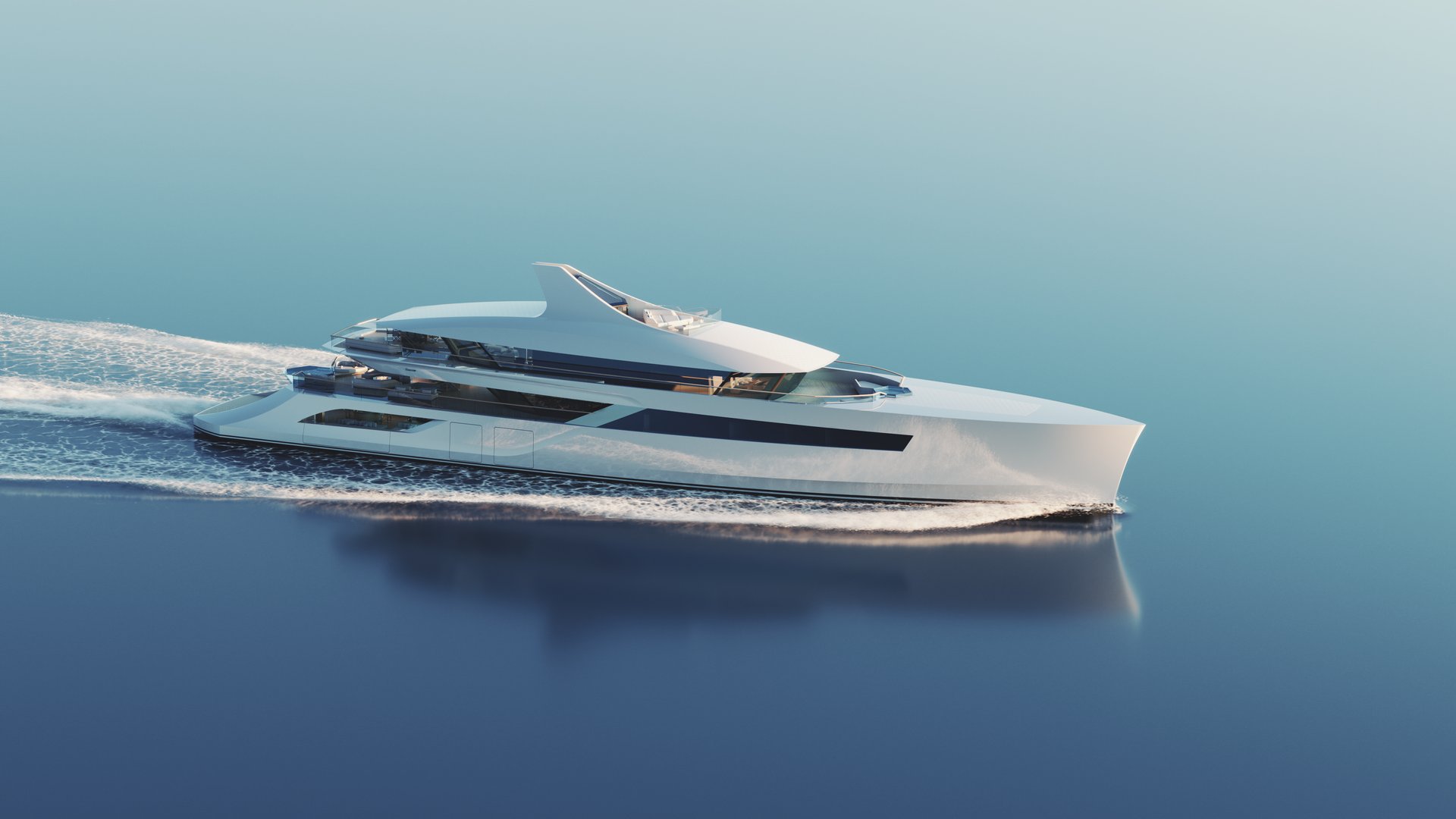

Designing a yacht is one of the most complex challenges in engineering. Far more than a luxury vessel, a yacht is a floating city with her own power generation, waste treatment, air conditioning, and accommodation for dozens, occasionally hundreds, of people. Add propulsion, stability, safety, comfort, and performance requirements, and you begin to see the scope of the task. Every choice, from hull shape to interior layout, influences countless other factors. This is why naval architects and designers use the ‘design spiral’, an iterative method that balances specifications, weight, structure, stability, comfort, and cost until the optimum design emerges. At Feadship De Voogt, our teams refine each iteration, combining experience and data from past projects with the specific vision of each client. The result is a yacht designed from a blank page to meet exacting requirements, tailored to the owner’s lifestyle and expectations at sea.

A yacht is a complex structure to design. It is a floating city with its own electrical power plants, sewage and wastewater treatment systems, ventilation and air conditioning. An average Feadship houses 40-50 people, but the bigger yachts can easily house more than 100 people.

Above that it has its own propulsion system and tonnes of complicated structural items like shell doors, swimming pools, tender cranes, rescue cranes, sauna’s, cinema’s. When finished we put her in the sea where the environment (sea) is constantly changing, we have to make it float, keep it stable and above all, have it strong and stable enough to withstand all forces from mother nature. And last but not least we have to think about comfort in terms of motion comfort, low noise levels and keep vibrations to an absolute minimum.

Also, we want to fulfil the owner's requirements for speed, range, beam, draft, number of guests etc.

Within this complexity, changing one component can have a large influence on other components. That’s why Naval Architects and ship designers use the “design spiral”. This shows that the design of a ship is not a linear process, but an iterative cycle.

On the axis of the design spiral, you have the specifications, General Arrangement, Preliminary Power & Weight, Hull lines, Hydrostatics, Technical Arrangements, Structure, Speed Power & Range, Lightship Weight Estimate, Capacity Trim & Stability, Motion & Comfort, Cost Estimates

The design spiral starts at the outside, spiralling in towards the optimum design in the centre of the spiral.

To finish an iteration, the Naval Architect must do a 360° circle around the design spiral. At the start of the new iteration the new principles of the design will be set, and a next iteration will take place, until you reach the optimum design.

The Naval Architect goes quickly through the first stages, but every iteration (full circle through the design spiral) will add more detail and therefore more time.

At Feadship De Voogt, we do multiple design iterations starting in a concept design where we lay down the first sketches, up to detail engineering where we put in final tweaks to design.

Although you want to reach an optimum design point in the middle this will be very hard to achieve, due to the various axis of the design spiral as some of them are counter effecting the others.

The optimum design point differs per client. What's important for one person can be of less importance for another person, for instance range; we have clients who want to cruise the world, some of them even around the poles, where ice can play a crucial factor. These vessels need to be strengthened in the construction, as the colder regions require more insulation. On top of that there is the additional required fuel, all of this brings more weight and volume to the hull.

Others want to have lots of open decks and a sleek design for spending their holiday in the Mediterranean or the Caribbean and doing short voyages from A to B, which will create a yacht with less volume.

You can imagine there are clients who would like to have a wider vessel to get more interior space. This will have an impact on stability, resistance and sea keeping. The wider beam will have negative effect on resistance. In order to keep the same top speeds, you have to increase engine power. If the starting point was a comfortable yacht and you increase the beam, the boat will be less comfortable. Therefore you could make the decision to add more steel higher up in the boat. To bring the comfort back to desired values, adding more weight would mean that you further have to increase engine power, with a negative effect on noise levels and vibration level. Alternatively, you can decide to reduce the weight or change top speed. It is up to the designer and the Naval Architect to fulfil and adjust the design to meet the requirements of the client.

The Naval Architect wants to get as close to the optimum as possible in the first iteration. The trick to achieve this is to have a solid starting point, as close as possible to the optimum design from the beginning. And here comes experience into play. Our designers and Naval architects have a lot of experience and due to the number of yachts we deliver each year, we have a large database of projects which helps us to get to the optimum as quick as possible.