Feadship is harnessing Big Data, machine learning and automation technology to build better, safer and more efficient yachts. What are Feadship’s thoughts, and those of other industry leaders, on the future of smart superyacht design?

We live in the digital era, also in our daily lives. Our phones, our home appliances, our cars – they are all connected and use data to make our lives easier. It’s exactly the same with yachts, so we’re talking about how we can build better yachts using that technology and how we can improve life on board.

Learning from data is the key to improving products in multiple industries – including yacht building. Feadship knows this and collates masses of data via remote monitoring to inform the R&D process and ultimately build better yachts by opening the gateway to smarter solutions.

Big Data

A yacht is “a system of systems”. Data from these systems is logged every three seconds and stored on onboard computers that can be accessed remotely with permission from the yacht’s owner. Combining and analysing this data over time provides insight into historical performance and operational profiles when designing new builds. It also means operational help and advice can be given to crews.

In our experience there are two matters that really matter to Feadship owners: the first is maximizing enjoyment, and the second is maximizing value. Data collection and remote monitoring can help us achieve both those goals.

The most important element is that data collection can be used to remotely assist the crew when there’s an issue on board: every now and again something breaks down – even on a Feadship! Being able to remotely monitor data and jump in when something goes wrong means we can assist the crew with advice on the spot.

According to Marco Scholtens, Innovation Manager at NMT - Netherlands Maritime Technology, data monitoring is still a young but exciting development with the potential to benefit the whole marine industry because it helps not just shipyards like Feadship to improve their products, but their suppliers as well.

“Until fairly recently, suppliers had very little information or insight after delivery into how their equipment and systems were performing in an operational environment,” he says. “Collecting sensor data provides them with much needed feedback.”

Added value

The first step in this process is better understanding how yachts are used, how their systems are operating, and making deductions so we can improve our designs.

To do this effectively, Feadship needs also to develop new methods – perhaps by harnessing AI or machine leaning – to rapidly analyse and diagnose data. Some of this raw data is revealing. Based on around 600 years of collective data from multiple superyachts, Feadship has deduced that they are sailing on average only 10% of the time; 33% of the time they at anchor; and 57% of the time in a harbour or marina.

For the bigger yachts, this means that hotel loads account for around 40% of the fuel consumption and 60% for navigation, while for the smaller yachts it’s the other way around. Moreover, the most frequent distance sailed is only about 30 nautical miles. This is only scratching the surface, but it’s the kind of information we need to design more efficient vessels.

Feadship has also installed optic fibres on its own superyachts to measure the flexing of the metal structures, because ever bigger windows and hull doors have to be balanced with adequate stiffness. The resulting data can be used to calculate thermal loads, wave loads, trim loads and weight loads in order to optimise structural design and engineering.

We’re collecting one terabyte of such data per year from four yachts. We can even detect which is the sunny side of the yacht, because the yacht will bend fractionally more when the steel or aluminium heats up.

The collation conundrum

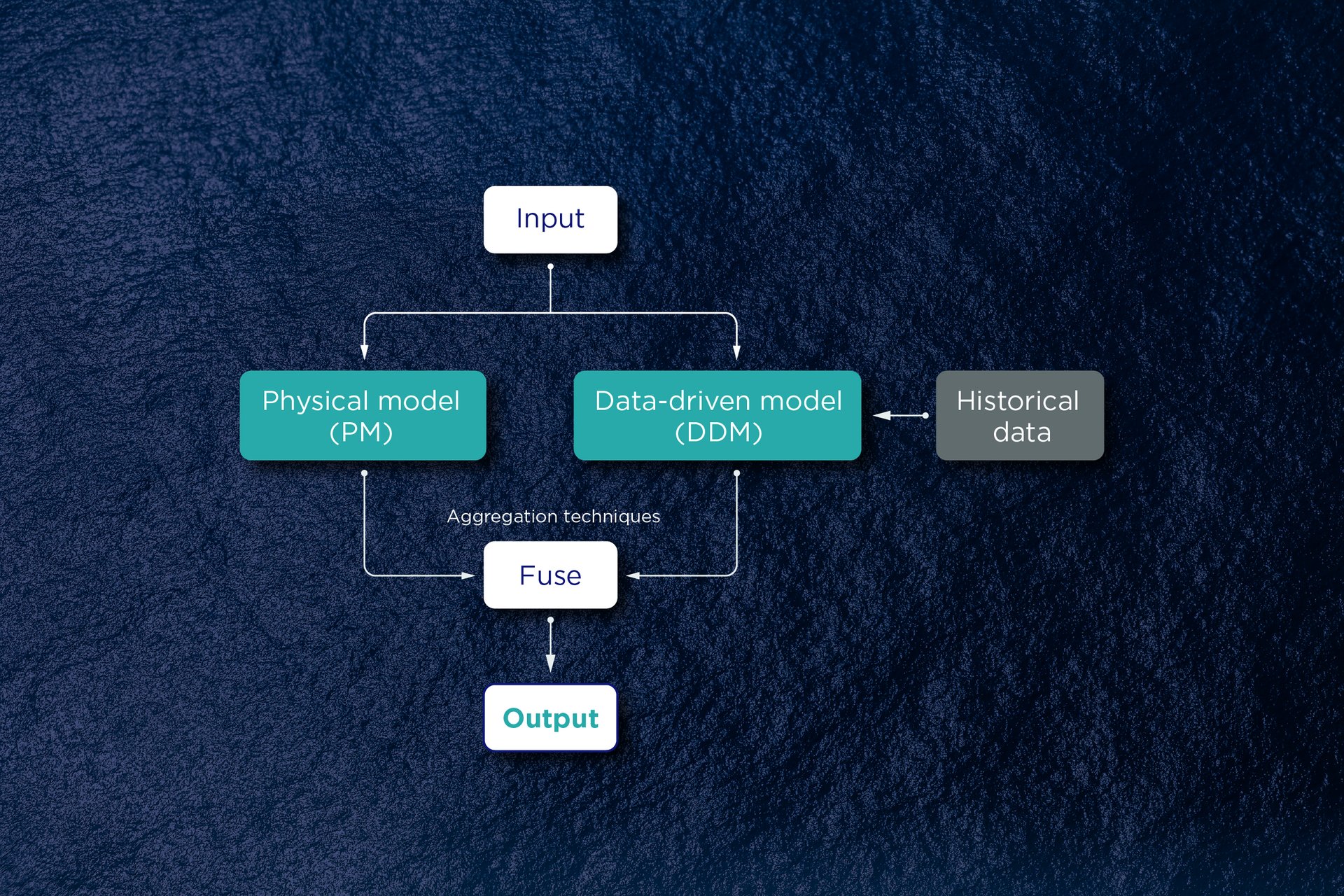

One of the biggest challenges that Feadship is facing is how to make sense of the huge amount of data it is collating. To do that it is drawing on the power of machine learning and AI to extract the most relevant data inputs. This not only makes the process less complex, but also helps in terms of prediction accuracy.

“Integrating data science into the design and operation of yachts is not only state of the art, but necessary as we aim to make ship design more intelligent,” says Dr Austin Kana, assistant professor at TU Delft. “The work we are doing in cooperation with Feadship is at the forefront of these opportunities.”

Increased digitalisation raises the question of cyber security, but here again Feadship is ahead of the game. “We already comply with the latest standards, but apart from the technology it’s important to know that procedures and training are also very important,” says Jan van Bekkum, Director Portfolio Management & Innovation at RH Marine. “In the event of anomalies or a cyber-attack, the crew must be prepared and be able to deal with it.”

Automation & navigation

Digitalisation and data collection further enable the automation of navigational functions. The proliferation of satellite networks like Starlink, for example, combined with traditional radar and camera surround view, can aid situational awareness and even predict the effect of wind and waves on course and heading. Close-proximity scanners can automate berthing in crowded marinas, much like similar technology can park our cars without the driver having to touch the steering wheel.

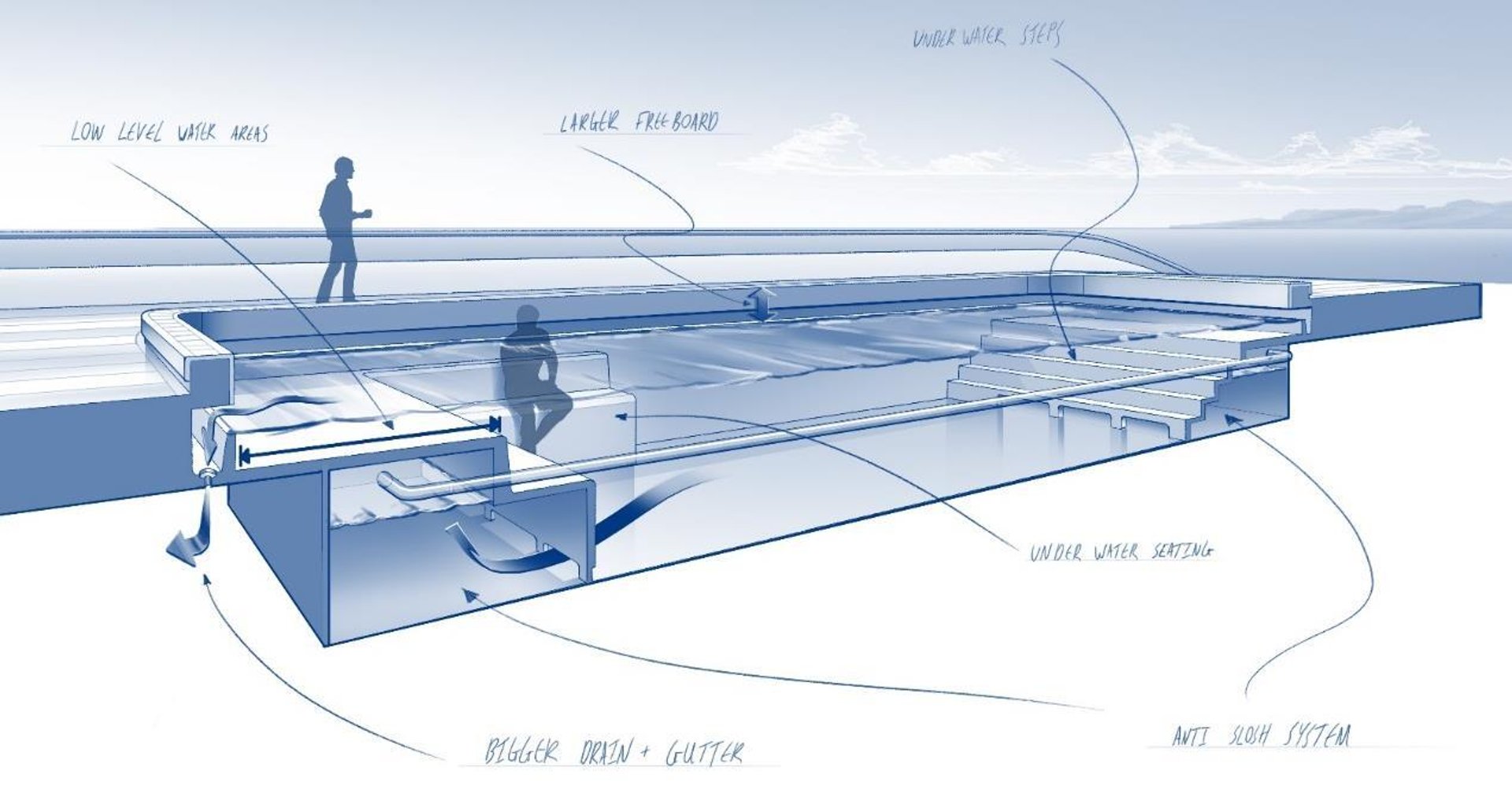

In the long term, these developments may influence the layout of future Feadships. The wheelhouse, for example, currently occupies a prime piece of real estate on the bridge deck. But data monitoring and AI could advance automation to such a degree that the wheelhouse can be located on the lower deck with a guest deck above and a forward-facing master stateroom on the upper deck – even on a 50-metre yacht. In this scenario, there is no need for a wheelhouse with clear sightlines fore and aft, which in turn will revolutionise the visual appearance of superyachts.

Many of these technological developments have already been integrated into Pure, Feadship’s concept design, which has future-compatible propulsion and a lower deck command centre. The Feadship Foresight programme provides further assistance to the captain and crew with regards to situational awareness, motion prediction, routing, on-board comfort and finding the most fuel-efficient way to travel between locations.

“At MARIN we’re currently building a new simulation centre and one of the objectives is to be able to test these innovations at a very early stage,” says Egbert Ypma, Program Manager Unmanned Maritime Systems at MARIN. “So way before building a yacht, you can play with variations and see how they affect onboard operations in a way that is as realistic as possible.”

Will these developments ultimately lead to unmanned superyachts? Almost certainly not, primarily because the crew aboard a yacht has other functions apart from navigating the vessel and first among these other tasks is looking after the guests. The ultimate aim of automation technology in a yachting context is to make life easier for the crew, more comfortable for the guests, and safer for everyone.

To find out more on this topic, tune into the first episode of UnIQ by Feadship, our interactive broadcast streamed live from Amsterdam.