The recent launch of the 46.22-metre Feadship Como once again drew attention to Feadship’s pioneering use of glass onboard superyachts. The owner requested some unprecedentedly large windows in the hull of Como and a wealth of glass in her superstructure. Like every custom project at Feadship, the client’s requirements were met in style. And following on from other recent launches that have highlighted the art of glass such as Hampshire II, Musashi and Venus, thoughts now turn to the next logical – but seriously complex – innovation, namely using glass structures to also support structural loads from the decks above.

The advance of technology in the use of glass is radically changing the look of superyachts in the same way that it transformed land-based architecture. Today glass determines the look of most buildings, and its use on large yachts has been constantly on the rise over the decades. In 1960 the average proportion of glass within yacht silhouettes was around seven percent, a figure which had doubled by 1990 as windows became larger, were placed closer to each other, and played a far more prominent role in styling.

From land to sea

Feadship has always sought innovative ways to use new and existing materials, and there have been many custom builds over the decades that pushed the window in terms of bathing yacht interiors with natural light. The current developments can be traced back to the first of the annual Future Feadship Concept designs in 2006 called X-stream. “As more and more glass is used on buildings and large structures, our clients have the right to expect the same on their superyacht,” says Bram Jongepier, manager of knowledge development at Feadship and responsible for the development and execution of Feadship's R&D programme.

“We received a very enthusiastic response to our idea of offering a fully glazed superstructure and a glass observation area in the bow as shown on X-stream. And this encouraged us to initiate a long-term research programme that would make possible the use of more glass. In essence this focused on the use of very large glass panels, the deployment of glass for strength, and the influence that glass has on comfort levels inside a yacht such as acoustics and climate.”

Through the 20 percent barrier

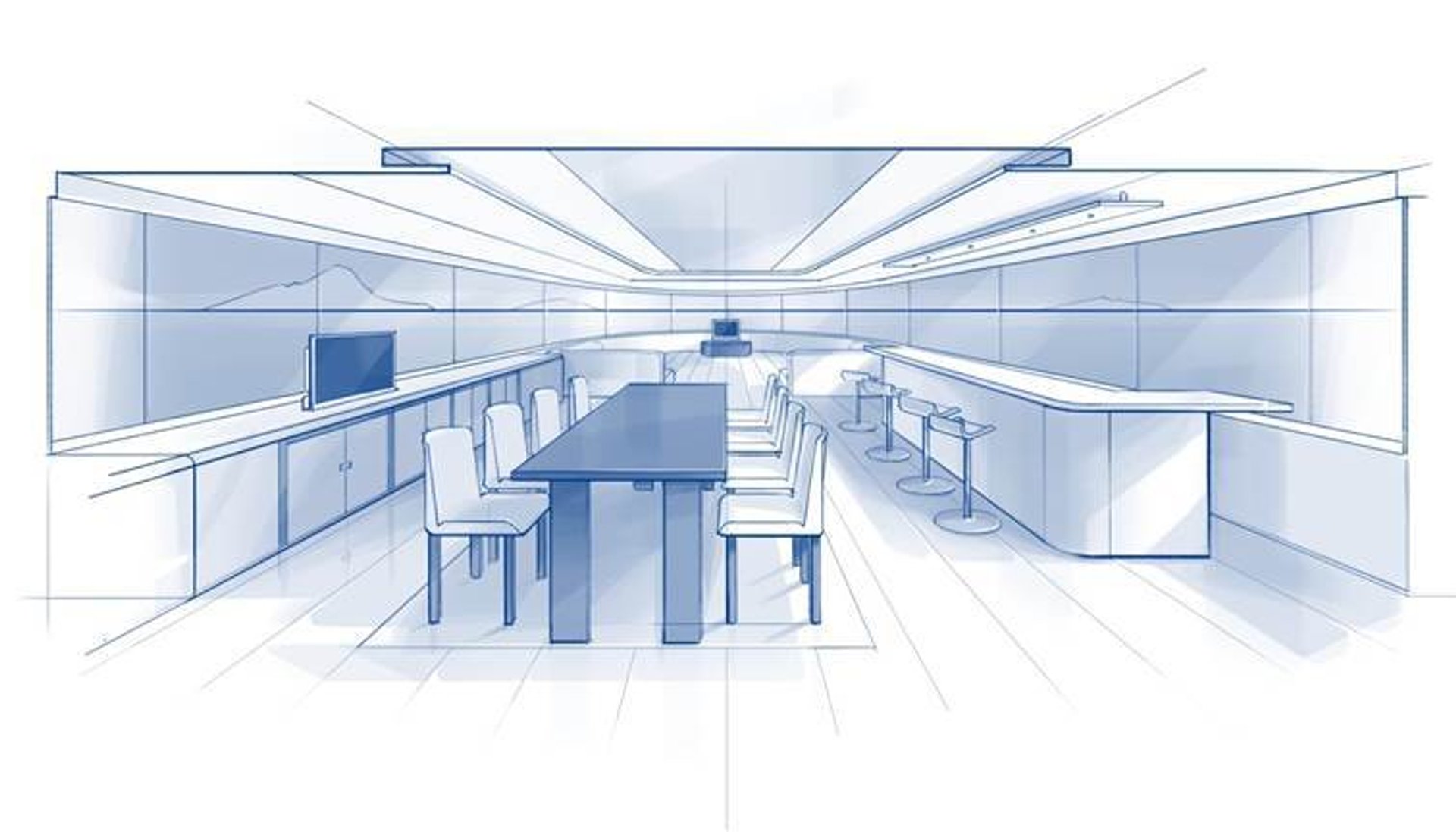

Glass panes have a major impact on the routing of ducting, piping and electrical cables. A layout concept was developed with a structural core inside the yacht containing stairs, ducting and technical spaces similar to buildings. The central core keeps all outside walls open and creates an impressive interior with views all around. This concept was used in the 88-metre Feadship Mushashi, launched in 2010, where the structural elements around the luxury interior spaces were kept to a minimum. Air conditioning rooms were placed on the lower decks to keep the layout of the upper decks free from any technical areas. The proportion of glass to metal in Musashi’s exterior profile is well above 20 percent, an impressive feat for a globetrotting superyacht that faces everything the oceans can throw at her.

Various Future Feadship Concepts have been fitted with larger window panes and

underwater windows. Aeon, unveiled in 2009, featured glass in the hull and showed how

large windows at the waterline could offer amazing views on the oceanic world outside. The

idea has since been brought to a degree of reality on the 78.50-metre Feadship

Hampshire II, launched in 2012, which offers an underwater viewing port of over one metre

in diameter from the wine cellar on the bottom deck.

Her name is Venus

The next revolutionary project to showcase Feadship’s heart for glass was the 78.20-metre Venus, launched in a blaze of publicity in October 2012. This head-turning yacht was created in a unique collaboration between the client, Philippe Starck and Feadship. Venus is special in many ways, but it is the use of glass which perhaps received the most attention.

Bram Jongepier takes up the story. “Aluminium boats have a considerable degree of flexibility and Venus is the longest aluminium yacht in the world to date. We carried out lots of research into the degree of deflection that would occur during the lifespan of the boat using model testing and Finite Element Model (FEM) calculations. The results showed that the deflections would be far in excess of what would usually be the case due to the large panes and flexibility of the boat. This meant we had to devise new ways to connect the glass to the boat as standard rubber bonding was no longer suitable.

“The challenge was that while the normally used elements connect well to the paint system, those required to cater for the deflections were silicon-based – and silicon and paint systems do not mix well. To solve this, a connection to a steel ring was fitted to the glass in the factory. This steel ring was subsequently fitted in the construction of the yacht in a double connection system (a flexible connection based on silicon and a rigid steel ring connection to the yacht). A conventional seal was added and even if this would be ruptured in a storm the glass itself would stay in place due to the flexible connection behind. This remains theory in any case as Venus has come through some heavy weather and even the conventional seals have held.”

Testing, testing

The very large windows of the pavilion deck onboard Venus required close cooperation between Feadship, Lloyd’s and glass expert Eckersley O’Callaghan in order to meet the owner’s demands in a safe and responsible way. Normal windows are tested full scale in a steel construction using water pressure to see whether the construction will hold. Venus’ pavilion windows measure 10 x 2.4metres, however, and there’s no testing facility for such a size. Moreover, the connection system for these large windows is very different as there is only a connection on one side with the windows resting on a couple of supports.

“After lengthy discussions with Lloyd’s we carried out a four-point bending test,” explains Jongepier. “This involved a metre-wide strip of the proposed window laminate, supported at the ends and pushed in the middle with a load derived from Lloyd’s regulations. The laminate passed the test and we could go into production.

“Once Venus was launched we could measure actual hull deflection with the tank loading centred and completely to the ends. We were also able to check the accuracy of our FEM calculations – the first time anyone has had access to real-life feedback on the computational models used. Crucially, we were able to replicate the results of the tests to an accuracy of 10-15% – an impressive figure for such an extraordinarily complex product like a superyacht.”

Como goes further

And then came the newly launched Como. “Here the superstructure glass is placed on top of the metal rather than being set into it, creating a continuous surface,” continues Jongepier. “These glazed side panels give spectacular uninterrupted views from the owner’s

stateroom. And the exceptionally large windows in the hull go way beyond what is permissible from a regulation point of view. We had to convince Lloyd’s that we were able to make windows suitable for that location and size, and prove that the glass laminate would hold.

“Moreover, the glass covers the structure on Como in a continuous glass band. We had learned from the Venus project that you have to measure and correct the complete superstructure in the paint and filler works to be able to make a fair transition from the paintwork to the glass and back to the paintwork again. The gloss lines have to be continuous... And on Como they are.”

According to Jongepier, both Venus and Como go way beyond the norm in terms of the attention paid to these surfaces. “A 3D scan is made of the finished structure around the place where the glass will be. The prescribed amount of filler is then used based on that 3D measurement. Only after measurements have proved its accuracy will the final treatment of the finished surface get underway.”

Bearing loads

A further development is Feadship’s work on the capability of glass to bear loads. Until now glass has not been considered to be part of the structure and, as we have seen, loads are carried by the window frames and the superstructure around it. But as glass forms an ever larger part of a yacht’s exterior, such an approach cannot continue indefinitely. Load bearing glass structures will create a stiffer construction with a lower weight. What’s more, they will open up the possibility of no longer having to have structural sections between the windows.

Feadship has therefore developed techniques for using glass as a load bearing part of the structure. As glass is very sensitive to load concentrations, an important area of this development is the way that stresses are transferred from an aluminium or steel structure into the glass.

Jongepier: “Venus had these incredibly large panes around the pavilion weighing around seventeen tonnes and yet they were not being used to support the roof above. However, in order to have no risk of vibrations in the roof, we had to make a very stiff cantilevered construction whereby the roof is actually floating above the windows. Supporting the roof by the window would have saved tonnes of aluminium work.”

Increasing stiffness

Feadship’s research into using glass in a structural way has examined what happens to the load distribution, stress flows and all kinds of discontinuities in a design. Taking Musashi as an exercise, all her windows were made structural in an FEM model and connected rigidly to the rest of the structure. The results were impressive, showing that the yacht would be at least 25 percent stiffer if the glass were to actually take the load.

“This has implications for more than just the aesthetic use of glass,” comments Jongepier. “Long boats are hard to make stiff as they have such a slender construction. Go beyond eighty metres and the global stiffness of the boat takes on a new dimension in terms of hull girder vibrations. A 25 percent increase in stiffness would therefore be very interesting indeed.”

In 2012 Feadship initiated a study into load bearing glass that focused on specific locations in the yacht: local, not global, loads. As an exercise, the load of the wheelhouse roof of a 45- metre Feadship was placed on the windows. After a wealth of calculations it was discovered that by increasing the thickness of the front windows from 14 to 30 mm they could support the roof. Five full-scale tests were then carried out which proved that an enormous amount of weight could be placed on top of the windows.

For regular windows a normal load is prescribed by class of about three tonnes per square metre. The roof above is also considered a design load, and this was also transferred onto the window (around three tonnes). Lloyd’s regulations require that windows be able to support four times the normal load without breaking. The tests put four times the normal load on the window and then started adding the deck load (compression load) too. It took more than 15 tonnes of weight before they actually broke.

Through the glass ceiling

“This is the stage at which we are now,” concludes Jongepier. “We are convinced that we are able to load our windows with the load from the deck above in a local situation. We know how thick they need to be, we know how to test them, and we have already discussed this with the class authorities. Ovens of the size required to bend giant glass panels are now available, and Feadship has the design and construction expertise to ensure total safety at sea. Now we are working with various designers and potential clients on something truly spectacular that will reap the rewards of all this research... There is much more glass on the horizon!”