As the world changes rapidly around us, a primary mission for Feadship is to develop a sustainable and inherently flexible fuel and power system that will secure the long-term future of superyachts. Methanol is emerging as one of the most common alternative shipping fuels with various technical developments underway to make it suitable for our industry.

For the past decade I’ve been working on finding solutions to increase the efficiency of yacht systems and non-fossil fuel alternatives, with an emphasis on what’s practical for superyachts. Being a significant macro-economic driver, the fleet of very large cargo vessels, like container ships, dominate the marine fuel transition. The industry traditionally revolves around cheap low-grade bunker fuel, so any non-fossil alternative has to incorporate feasible costs and efficiency.

The challenge is to produce new chemicals like methanol, ammonia and hydrogen in a cost-efficient way from scaleable feedstocks. Not all bio-feedstocks are scalable: we don’t use enough cooking oil, for example, for that to be truly sustainable. Solid organic waste, such as waste from trees or agriculture is possible, as is renewable electricity. Ultimately, the science comes down to what can be produced at what price…

A unique sector

Yachting industry emissions constitute some 0.5% of the emissions of the entire shipping fleet, making it hard for us to steer developments (big respect though to owners investing on a personal level in the energy transition). As a sector we have to understand what is happening and adapt accordingly. It’s clear that methanol is one of the best options for shipping, with ammonia deserving considerable attention too for various very large ship types. As the simplest alcohol, methanol is easy to produce from various feedstocks. Being a chemical commodity as well as a fuel alternative makes it suitably scaleable, and the aviation sector is already moving ahead with using methanol feedstock as a building block for synthetic kerosene (aviation fuel).

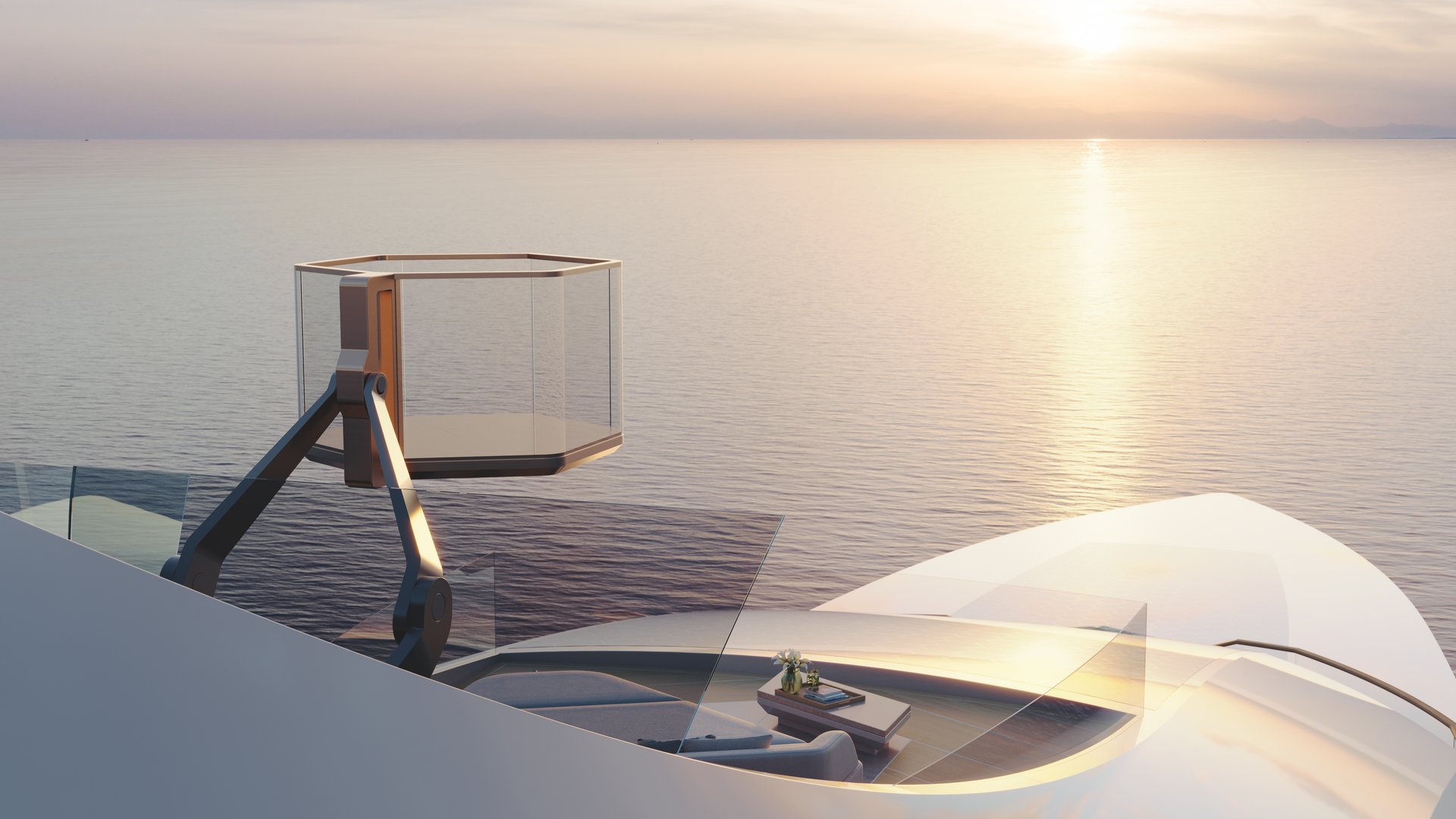

Understanding the above is a prerequisite as we turn to the superyacht world, where vessels are built in compact sizes with the high-value payload that are luxury interiors. With perhaps the exception of submarines, superyachts have the most technically compact and costly real estate of any vessel. Fuel and water are stored in tanks located in the void spaces surrounding the interior. Optimising these structural watertight compartments and any unused spaces in order not to sacrifice the payload is vital for our likely solution, which we call a multi-fuel system.

Alternative visions

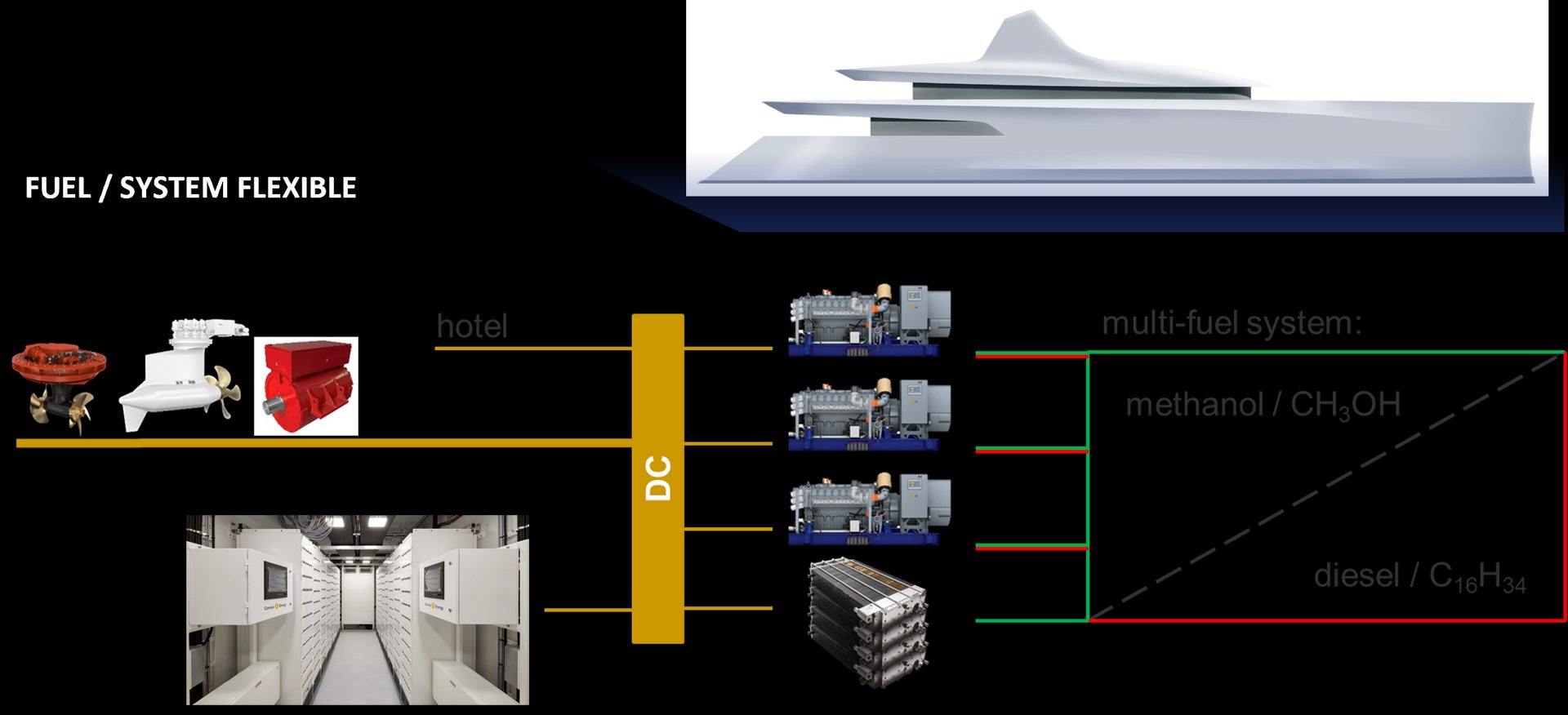

Avoiding setting in stone what the fuels of the future offers flexibility. All tanks, pumps and pipes will be designed and built to store diesel, methanol and similar liquid fuels that might become viable in the years ahead. Methanol is an obvious choice right now as it is becoming the most commonly used alternative fuel in the cargo shipping fleet, with over 400 vessels already in build. The supporting worldwide infrastructure of methanol bunkers and distribution facilities should also become available to yachts over the next decade or so. With some 50 million tonnes of annual green methanol announced to be produced by 2030, a great deal of headway is expected.

But there are other options potentially in the (literal and metaphorical) pipeline for our multi-fuel system. Increasing demands for sustainable aviation, for example, may well lead to greater availability of paraffinic fuels like kerosene produced from electricity. Diesel production is another part of this production process and the same facilities could offer that as a sustainable choice for owners looking to sail from, say, Gibraltar to the Galapagos islands in one go (a range that is not possible on methanol alone, which has less than half the energy stored for the same volume of diesel).

Tech talk

A number of key technical developments are related to this transition. Firstly, we are working on simplifying fuel systems to ensure they are inherently and passively safe. This involves partnering with industry and class societies to create systems that remain compact. We’re looking at ways to switch between fuels in the same tank cluster, taking contamination into account and its likely effects on engines and fuel cells.

Then there are the power systems themselves, with flexibility again the crux. Dual-fuel engines are being developed that may run on methanol and a small part of diesel, a non-fossil alternative of course, for the ignition. These engines will also run on diesel only to secure the maximum range and provide the flexibility on the short and longer term. While different OEMs are working on this and third parties are offering conversion kits, progress is currently slow.

Fuel cell potential

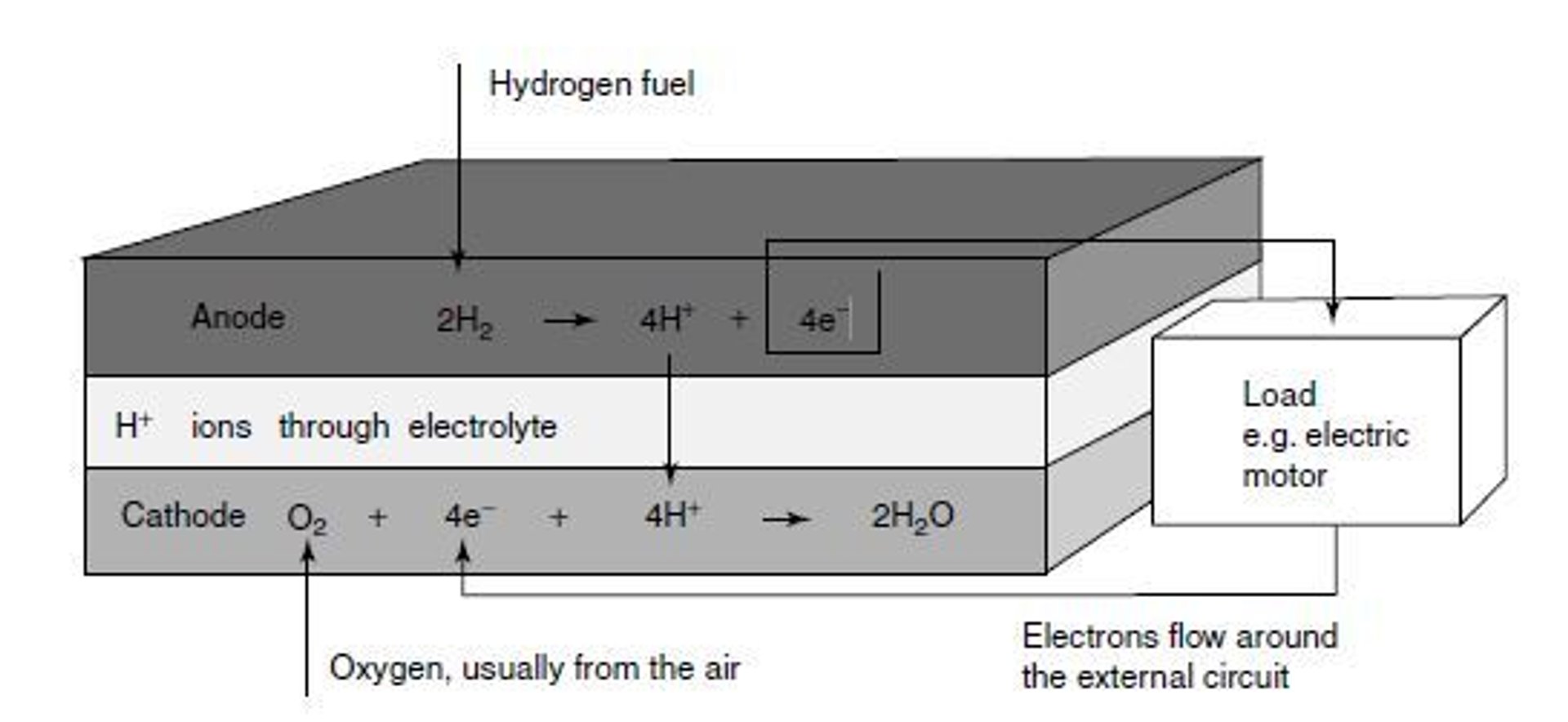

Another technical aspect to mention is methanol’s potential for fuelling fuel cells. These electrochemical cells would be ideal for the use profile of superyachts, which spend some 85% of their time stationary (at anchor and berth) up with a low load profile in places where local emissions often cause harm. They offer an even quieter onboard experience for owners and their guests and avoiding any local emissions further improves life onboard. The integration of a multi-fuel system with the main electric propulsion would allow you to swap engines for fuel cells in the future, offering an inherently flexible power system too!

"If you want to go fast, go alone, if you want to go far, go together" Cit.

Collaboration matters

Let me end by stressing saying that none of these developments can be tackled in splendid isolation. An often-heard credo in the Dutch maritime cluster is "if you want to go fast, go alone, if you want to go far go together." Feadship is heavily involved with other industry leaders in the MENENS project, focusing on R&D issues related to improving the performance and reliability of methanol-based power and energy systems. Another initiative is the Green Maritime Methanol consortium, which we started in 2018 with a few other parties and now has over 30 major contributors.

These kinds of cooperation are the only way to achieve lasting results and push back against the impact of a global emergency, which is already very apparent for the superyacht sector as the Mediterranean becomes a climate change hotspot. Embracing a multi-fuel system now will certainly add to the residual value of your Feadship in the future. These technical innovations will enhance your ROI and avoid the prohibitive costs of refits later down the road. In other words, buy in to change today and reap the rewards in every respect tomorrow.