IMO Tier III integration for main engines and generators

As per IMO decision of April 2014, yachts over 500GT must comply with Tier III emission regulations after January 2016. A continuation of Feadship’s standard diesel particulate filter system on the generators (DPF), a selective catalytic reduction system (SCR) will reduce NOx emissions by 80 %.

Engine suppliers are working on market introductions for modified engines, add-on SCR systems and integrated solutions. Feadship is pushing and challenging their suppliers to introduce this technology as soon as possible and make it suitable for use on board a Feadship yacht.

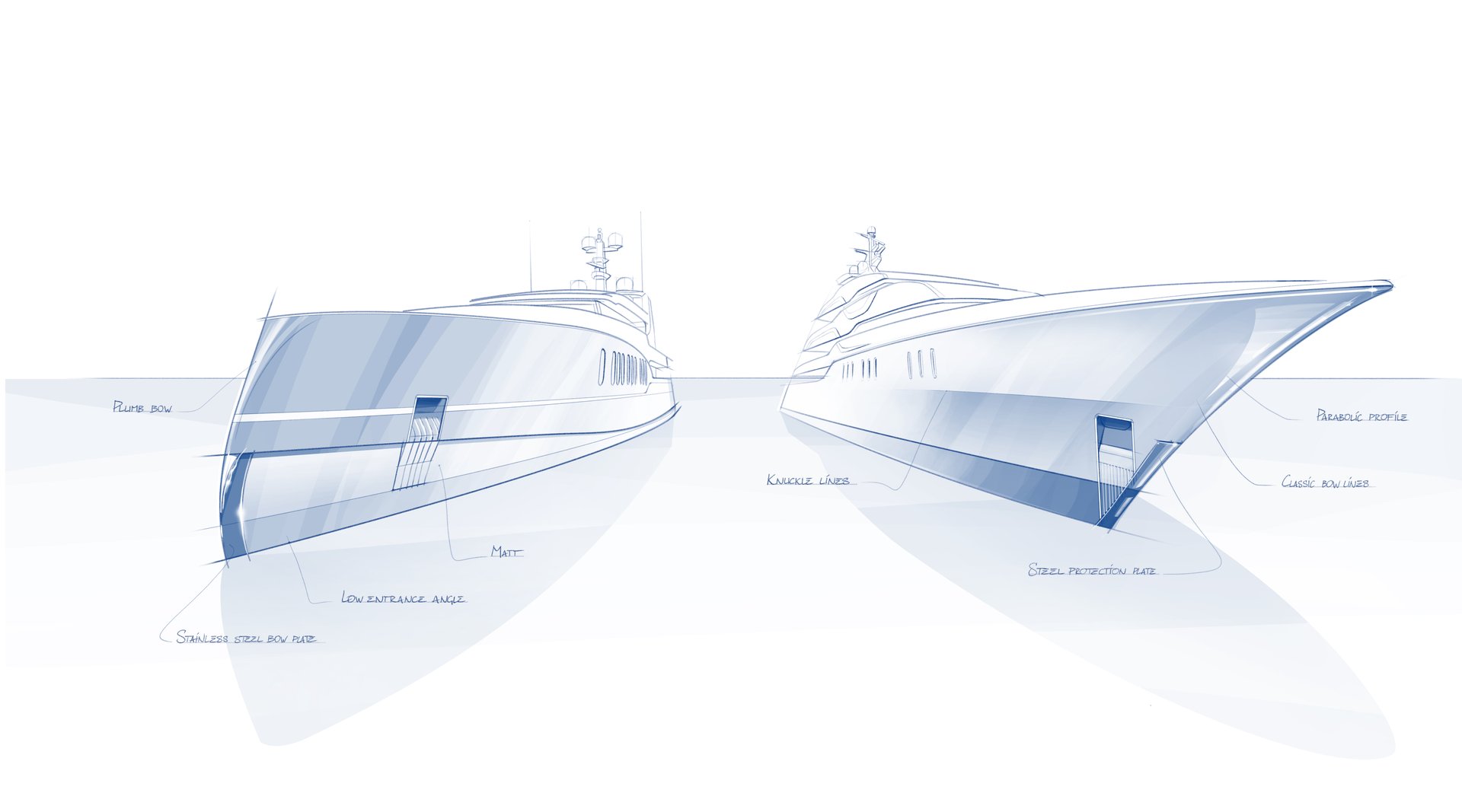

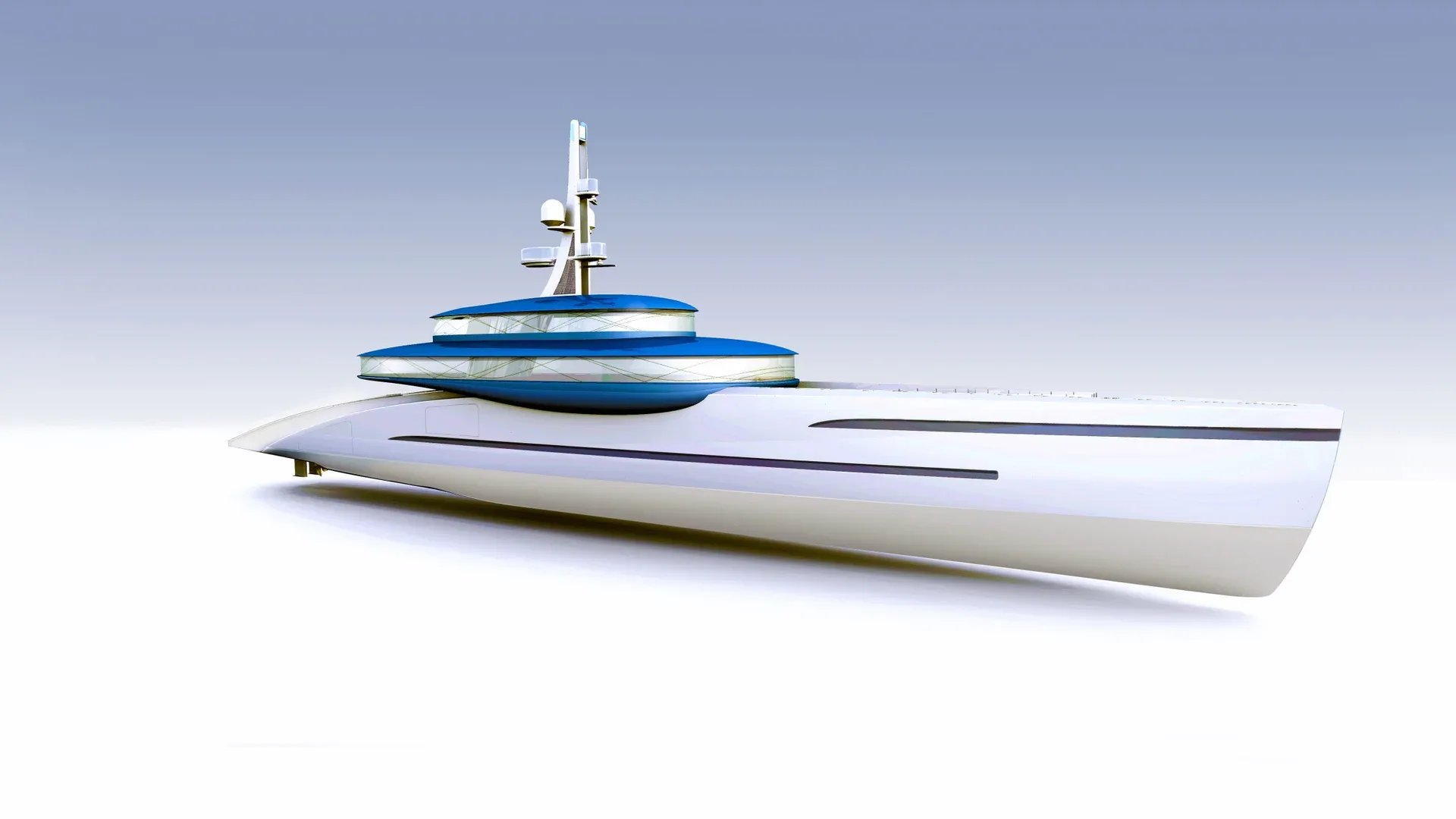

Matching design to customer operating profile

Each Feadship is as unique as her owner and the way he or she wants to use it. By defining a clear operating profile for each client and using this as a foundation for the design, the highest efficiency in cost and energy consumption can be realized. Varying from large decisions (diesel mechanical / diesel electric / hybrid) to small (window coatings, AC settings) the impact on cost and energy use in operation can be determined and designed on the basis of information instead of gut feeling. For most designs however a very efficient Feadship hull design is the best starting point, because propulsion will most likely be the largest consumer of energy.

Alternative fuels

Despite the hype, Feadship is not a believer in applying LNG on yachts. Short range due to the low energy density and very challenging bunkering and storage on board (unless you want a tank on deck) do not make this suitable as fuel. However, other alternatives exist. Feadship will be trailing with Shell Gas-to-liquid (GTL) fuel this year, which promises reductions in particulate matter and SOx as well as less engine fouling. GTL is available in The Netherlands only, but market introduction in Europe will follow shortly. Since it can be mixed with regular diesel, availability is not a big issue.

On the longer term, glycerine as fuel is a promising technology. Feadship is involved in the GLEAMS project, in which the British company Aquafuel Research in cooperation with Lloyd’s register has its first engines running on pure glycerine. Since glycerine is an edible by-product of biodiesel and can also be produced by saline algae, this has the potential to sail completely non-polluting and CO2 neutral. However, since availability is still low and engines need some modification, application in the large yacht sector (under Class) will take some time.

Batteries, PTOs and shore connection

The use of a large battery bank, in combination with a PTO from the gearbox and an enlarged shore connection is already a feature found on board a Feadship yacht. This provides the capability to load the generator to its optimum load, perform peak shaving (or peak supply), using the main engine to generate on board electricity (more efficient than generator set) and store land-produced electricity (which is also generated far more efficient than possible on board). Feadship sees more and larger application of batteries, in hybrid solutions and possibly in the much longer term a full electric ship.

Air conditioning systems

Although still the largest consumer in the hotel load, air conditioning systems have been made about 20% more efficient in the last couple of years by providing very good power management and AC setting control, compressors and heat pump integration. More techniques exist, and Feadship is always striving to create the luxurious atmosphere on board using the least amount of energy. Future designs will incorporate the results of Feadship R&D programmes investigating enthalpy wheels, phase change insulation, surface cooling, et cetera.