It is no stretch to say that a decade ago Project 821 would have been science fiction. This massive yacht is longer than a football field and taller than the Statue of Liberty, yet she can cruise with only water as exhaust, rotating torpedo-shaped pods push her in near silence and her keel holds a secret underwater viewing room. Balconies and terraces pop out of flush hull sides to create impromptu viewing platforms. Jules Verne would be awestruck. Taken together, the innovations of her propulsion and refinements of her systems mean the yachting world is forever changed. Not only is she the world's first hydrogen fuel cell yacht but she's the largest yacht built in The Netherlands to date. Five years in the making, Feadship Project 821 is the latest answer to a fundamental question: How far can we push hydrogen technology on superyachts?

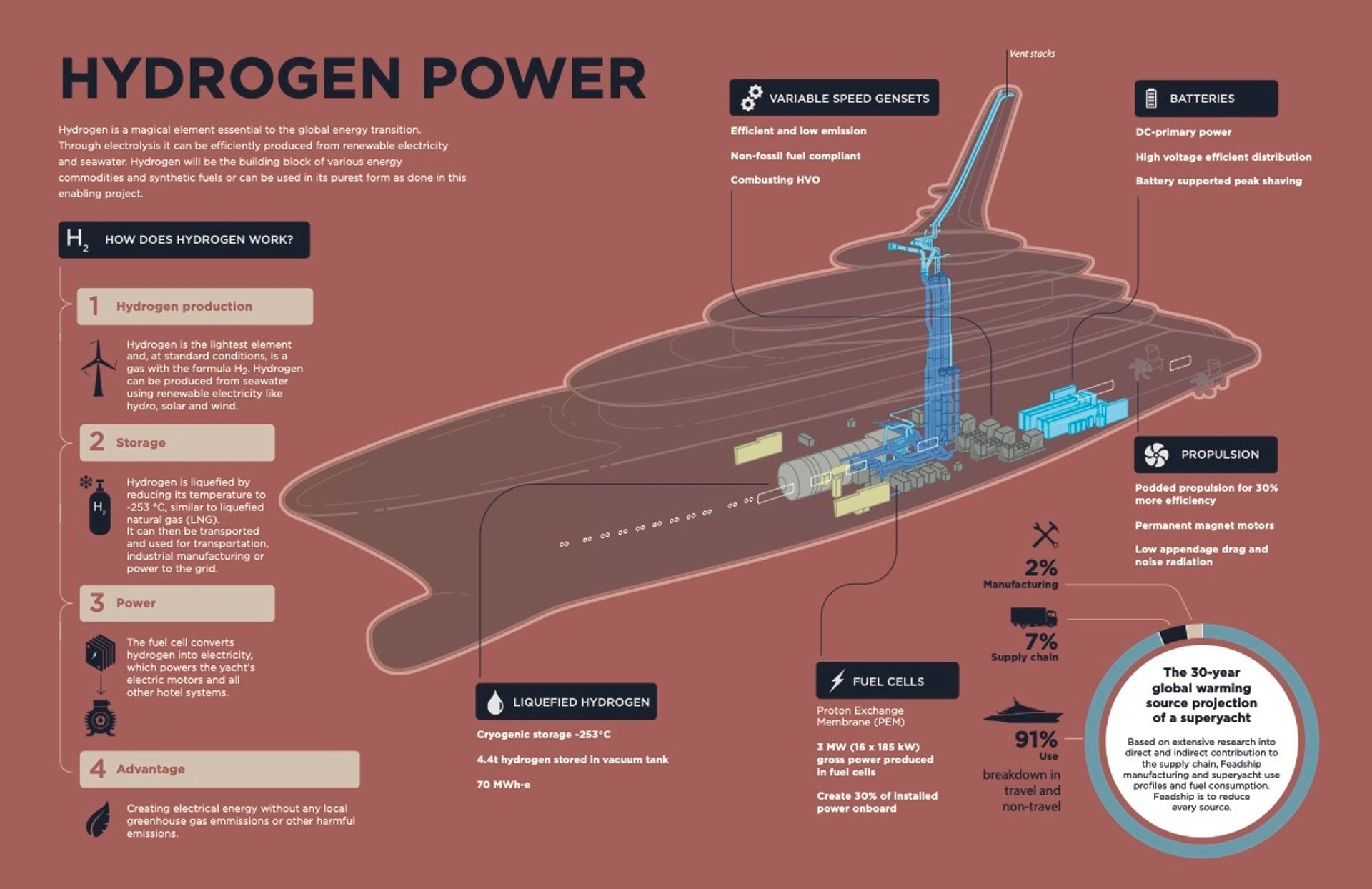

The bold, bid-winning response was a multi-faceted approach that lowered the yacht's environmental footprint from construction material selection to operation. Feadship delivered a solution that provides a zero-diesel approach for cruises between harbours or anchorages, and the operation of the yacht's hotel load and amenities with emission-free power from green hydrogen. "The aim has been to develop a new, clean technology not just for this project, but for the world," says Jan-Bart Verkuyl, Feadship Director / CEO Royal Van Lent Shipyard. The size of the proposed yacht – 100-metre-plus – made it a good candidate to explore pure green hydrogen as the fuel source. That a yacht pushing ship powering technology would be realised in a shipyard purpose-built to the highest standards of sustainability was lost on no one: the Amsterdam facility is powered almost entirely by district heating, waste energy and solar power.

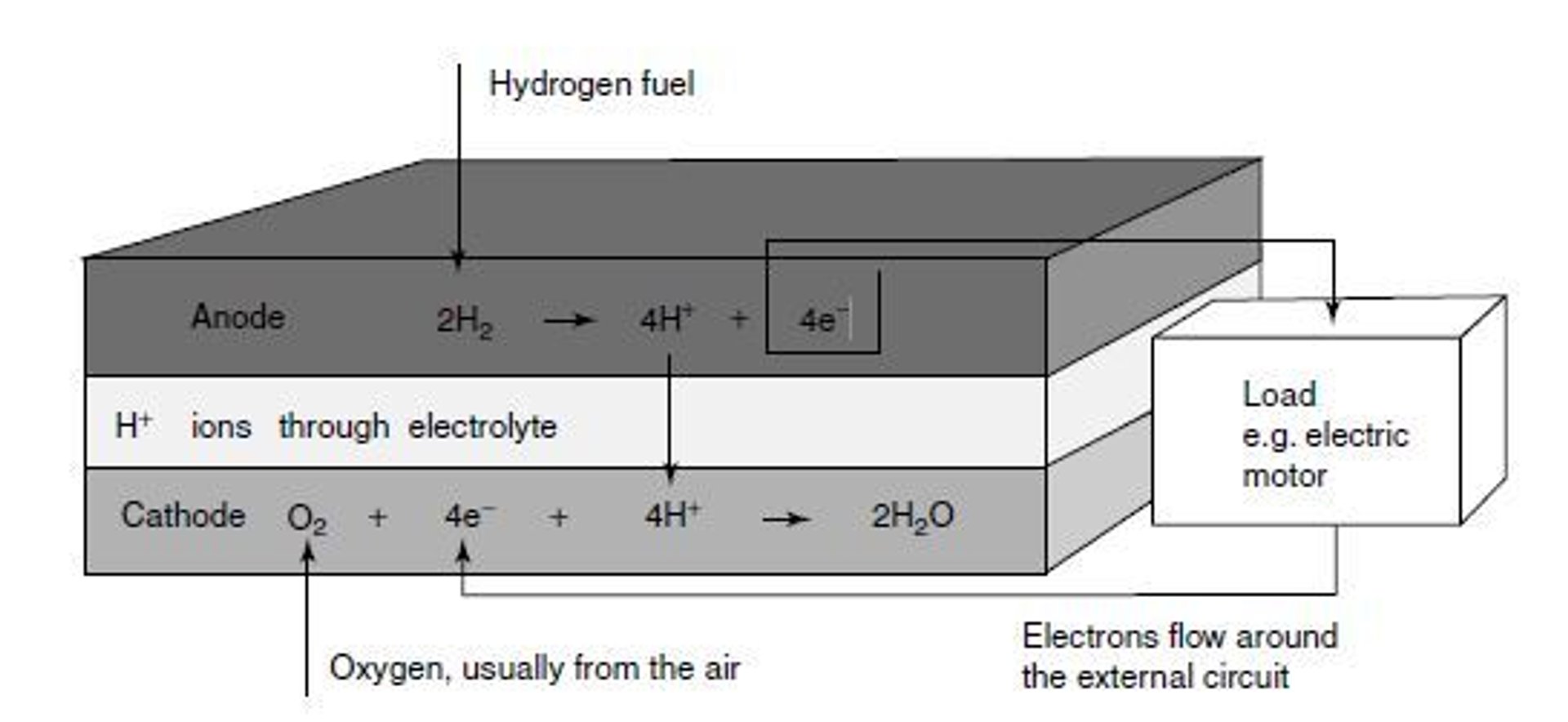

Feadship's R&D team has been researching hydrogen, among other fossil-free fuel options, as part of the company's pledge to develop "net zero" yachts by 2030. Hydrogen fuel cells, a combustion-free way to generate electricity, have water as their only exhaust. Although there are hydrogen fuel cell-powered cars and fuel cells have been used as the primary source of electrical power in human spaceflight for more than six decades, no high power applications existed in the maritime sector. When this project began in 2019, Feadship had to navigate the risk-based "alternative design route" as prescribed by the IMO, since prescriptive rules do not exist for hydrogen as a fuel nor the fuel cell systems. Seeking expert partners from allied industries, Feadship and Lloyd's Register developed appropriately scaled equipment, protocols and safety assessments that formed the basis of the new regulations, that will lead to the project certification upon delivery of the yacht allowing for international operations.

"The value of the research as well the development of class and flag safety appraisal for an entirely new type of energy generation is an advancement we are proud to have made available to all," Verkuyl says. Next year, for example, two long-route Norwegian passenger and car ferries will enter into service utilising the system pioneered with PowerCell Group for Project 821.

From the beginning, one of the biggest hurdles would be developing a reasonable way to store compressed liquid hydrogen below deck onboard a luxury yacht at -253°C. Investing in R&D for the required technology was seen as a necessary step to make the transition away from fossil fuel, and green hydrogen is one of the most efficient and cleanest options. When green hydrogen is processed in a fuel cell, the only by-products are electricity and water in the form of steam.

Light as a feather

Hydrogen is light – one cubic metre of liquid hydrogen weighs 70kg vs. some 800kg per cubic metre of nonfossil diesel equivalent fuel (HVO or e-diesel). However, safely storing it on a vessel requires a double-walled cryogenic storage tank (a large very well-insulated cooling box) in a dedicated, ventilated room. Although the volume of the cryogenic storage tank is about eight times larger compared to the equivalent amount of diesel (by energy) stored in the double bottom tanks, the overal space required to house the entire system in the holding room in the yacht requires a mere thirty times more volume compared to diesel.

Bearing in mind that the diesel is stored in a structural void space which cannot be used for another purpose, the impact on a yacht design of cryogenic stored gaseous fuels (like hydrogen) is simply massive and hinder full range application, according to Giedo Loeff, Head of Research and Development at Feadship. The entire power-generating unit, including the diesel generators, the sixteen fuel cell systems and the hydrogen tank are contained on a single level.

In total, the cryogenic fuel tank that holds 92m3 (some 4 tonnes) of hydrogen, the compact fuel cells, their switchboard connection to the DC electrical grid, and the vent stacks for the escaping water vapour, added four metres to the yacht's original specification length. Importantly, says Loeff, the fuel cells developed for Project 821 can also use easier-tostore methanol, a liquid fuel in ambient conditions. It does require an additional system, reforming with steam methanol into hydrogen. In an onboard process, steam reforms methanol into hydrogen where it completes the electrochemical reaction in the fuel cell. "Having gained so much experience realising Project 821, the next development steps using other hydrogen carriers, such as methanol, is relatively straight forward." says Loeff.

"Sustainability for superyachts today is about how to get the most energy out of what non-fossil fuel you can carry with you, what is the most efficient carrier and how do you covert that to propulsion? Fuel cells are a high Cap-ex item, but they are the most efficient way to power the propellors. "The fuelcell system used here already saves some 35 per cent on energy compared to running generators. With the next generation (methanol) fuel cell systems, we expect to even reach 50-75 per cent energy use reductions. Not only this will reduce the emissions, it is a very significant operational cost gain", says Loeff.

“Future innovations on fuel cells and onboard reforming of methanol to hydrogen are on the near horizon”

Even a yacht the size of Project 821 cannot carry enough liquid hydrogen to power a crossing, but Feadship could impact a yacht's carbon footprint where it is largest — generating electricity to serve the hotel load and to charge amenities, and perhaps, electric tenders. According to the Yacht Environmental Transparency Index (YETI), 70 to 78 per cent of a yacht's total energy use per year is to supply its hotel load, with heating and air conditioning making the largest demands. Thus, providing that electrical power via non-polluting hydrogen fuel cells has a swift and significant impact on a yacht's carbon footprint. And there is the added benefit of reduced noise. Fuel cell energy is created by an electrochemical process rather than combustion. It is nearly silent and there are very few rotating parts, making it a great benefit to those wanting noiseless operation at night on anchor.

For longer travels or when pure hydrogen is not available, the electricity powering the 3200 kW ABB pod drives comes from five MTU generators combusting HVO, a second-generation biofuel that reduces harmful greenhouse gas emissions by 90 per cent. The validity of powering the yacht's generators with HVO was tested and proven on various Feadships.

For those customers currently requesting Tier III diesel engines, Feadship has standards beyond the required catalytic converter. Feadship installs an additional exhaust filter to remove 95 per cent of the soot (diesel particulates) preventing smoke and fouling of the superstructure. These filters are accompanied by additional silencers to achieve the required noise levels on board.

Silent nights at anchor

While large battery banks are becoming an accepted way to provide enough power to operate generator-free for silent nights at anchor or to cruise no-discharge marine preserve zones, Project 821 stores a mere 543 kilowatt hours of energy – compare that to Feadship's first diesel-electric hybrid, 83.50-metre Savannah launched in 2015, which stored a megawatt of electrical energy. Project 821 doesn't need such a battery bank, her fuel cell technology can provide an entire week's worth of silent operation at anchor or navigating emission-free at 10 knots while leaving harbours or cruising in protected marine zones. Onboard Project 821, the batteries are tied into the electrical grid and used for peakshaving on power demands to eliminate a second generator starting or two gensets running wastefully when power demands drop. This solution means it's never necessary to run more than one generator to accommodate the entire hotel load.

Project 821 also features the most efficient waste heat recovery system yet developed, heating everything from the yacht’s interiors, Jacuzzis and steam room to the ambient air temperature, towel bars and floors in the guest bathrooms. Further savings in the hotel load will come from a Smart AC system linking sensors throughout the accommodation to an energy management system that automatically reduces cooling or heating in unoccupied guest spaces. "Fuel cells produce heat and water vapour as by-product so the big unknown was the relationship of the two power systems for efficient heat recovery," notes Loeff.

Project 821 has many superlatives, she's also the largest motor yacht ever launched in The Netherlands, just edging out Feadship's 118.00-metre LAUNCHPAD for flagship status. Despite the fact the two yachts have nearly identical LOAs, Project 821 has thirty per cent more volume. With five decks above the waterline and two below, her height is commanding – the owners' deck sits roughly 15 metres above water – yet the profile drawn by RWD is flowing. She also has the most hull openings of any Feadship to date including fourteen balconies that slide out from the 'tween deck space, nine massive shell doors, and seven large opening platforms, all of which create an impressive connection to the sea. The balconies are unnoticeable in the hull sides when closed but slide out at the touch of a button, carrying with them their side railings or glass side walls, meaning no crew are needed for the operation. When fully deployed, the balcony floors rise to become perfectly level with the interior room and as per contract are vibration-free.

The fresh design ethos from Studio RWD is as fully developed as Feadship's breakthrough engineering studies. With both the exterior and interior under the hand of one firm, the yacht is free of awkward spaces or poor transitions. The exterior is modern but not radical, just as the interior is chicly simple but not minimalist. It is a soothing platform for exploring the world, one where every need and comfort has been anticipated, and one based on understanding that real luxury is the experience of being on the water.

Project 821 is designed for family use and extended time aboard. Great care was taken to deliver privacy or separations between generations if desired, yet create destinations where the whole group could gather. With three fireplaces indoors, a firepit on deck, and sliding glass walls that can connect indoors for al fresco living −or not − it is a yacht for year-round, any season cruising.

As anticipated for a 100m+ yacht, there is a full deck devoted to the owners. This one, located above the bridge deck, is essentially an apartment with two bedrooms, twin bathrooms and dressing rooms, a gym and a pantry. An office and a conference room each feature a fireplace open to the adjoining living room. The principal stateroom is forward with floor-to-ceiling sliding glass walls that open on a private, shaded deck with a hot tub. The hefty 19-metre beam allows wide corridors inside and gracious side decks outside, perhaps inviting a stroll to the aft deck for relaxation or taking informal meals.

However, the owner accommodation extends beyond a single deck. A unique and completely private vertical owners' corridor extends to the lower deck as a four-story atrium. This includes both a spacious staircase lined with bookshelves and display nooks and an owners' lift. At each deck level, there are inviting private destinations to savour such as a coffee corner snack bar on bridge deck level, a library on main deck, and a private dining room with a hull opening creating a sea terrace and an adjacent ensuite stateroom on the lower deck. This water level space is charming in its simplicity and magical in its location. The walls and ceilings are either teak or woven reed giving it a very boaty atmosphere. RWD's design innovation creates, in essence, a secluded fourlevel townhouse on the sea within the much larger yacht. Unless one was invited in, these unique spaces would be completely unknown to others aboard the yacht; their corridor entrances appear as wall panels. Clever pantry locations and crew circulation pathways facilitate service.

Guests move through the vessel with their own centre of circulation, which features a glass elevator on the starboard side wrapped by floating stairs ending at spacious lobbies. Glass balustrades make sure that light and views from large windows at each deck won't be obstructed.

The guest accommodation is unusually flexible. Four spacious guest ensuites, each with its slide-out balcony, are on bridge deck, which is also a full walkaround. Inside, a long corridor links them to the bridge, a helideck forward that doubles as a court for pickleball or basketball, and aft to the upstairs living room flanking an outdoor living space with a lovely conversation area arranged around a firepit. Four exceptional VIPs on main deck can be arranged as a stateroom with an adjoining sitting room or divided into eight guest suites, each with its own balcony and ensuite. There are also two staff cabins, one on main and one on the lower deck, with access to the crew areas and staircases, and accommodation for 44 crew. Project 821 also has a hospital onboard that cleverly can be accessed by either the owner or guest elevator or the crew corridor. It has a dedicated HVAC system.

Throughout the yacht, designers used a palette of light neutral colours in textured fabrics and leathers. According to Project Manager Louwerens Hoving, there are more than one hundred different white and off-white fabrics and leathers on board, along with Travertine marble, rattan, fumed and taupe eucalyptus, and limed oak to create a luxe coastal vibe. Accent colours are generally in blue tones.

Ambient illumination

There is a strong emphasis on indirect lighting, toe-kick lighting, and backlit furniture features. Nearly every area has an interesting tray ceiling detail to provide ambient illumination. On the decks, LED strip lighting concealed under the edges of built-in cabinets and seating emphasises shapes – curves and circles being the dominant leitmotif. For overall cohesiveness, details such as door trim features and hallway railings repeat their shapes from deck to deck, but the materials change.

The lower deck's beach club lounge has four seating areas and dining options either under cover or on fold-out terraces. Also included are spa facilities with a hair and nail salon, massage room, steam room, sauna with plunge pools and gym. Five opening terraces fill the space with light and sea breezes. A Dolby Atmos cinema with seating for twelve on the tank deck below can convert to a children's playroom. But the ultimate space is the underwater lounge made by slightly widening the keel below the beach club. Six large windows made of two layers of 7cm glass nearly floorto- ceiling height share the underwater scene. An equally secret staircase connects it to the beach club.

Jan-Bart Verkuyl believes fuel cells will play an important role for yachts in the years to come considering their superior efficiency, low particle emissions and low noise radiation. "We have now shown that cryogenic storage of liquified hydrogen in the interior of a superyacht is a viable solution. Future innovations on fuel cells and onboard reforming of methanol to hydrogen are on the near horizon. For Feadship, the bottom line is that the decarbonization of Feadship's upstream process such as our extensive use of aluminium produced in a more environmentally sensitive way and the production of net-zero, carbon-free fuels or hydrogen carriers deserves utmost priority."