Computational fluid dynamics (CFD) remains one of the most accurate methods for predicting ship resistance—but even a single low-fidelity simulation run can take hours. Sietse Duister, a new AI engineer in Feadship’s Specialists Team, addressed two key challenges in modern AI, unlocking the ability to analyse hundreds of new hull forms. Days of work—now done in seconds.

For decades, naval architects have addressed the challenge of accurately estimating the resistance of vessel hulls—crucial information required for the sizing of ship energy and power systems. Traditionally, this task has been driven by the need to meet contractual speed requirements set by shipowners, thereby avoiding costly penalties. In recent decades, however, tightening environmental regulations have introduced new challenges to this process , as more sustainable systems tend to be less energy- and power-dense. The result? Design margins are tighter than ever, making highly-reliable resistance prediction a necessity.

“By requiring less training data, the new method makes AI practical in a sector where data is costly to obtain.” Sietse Duister

CFD: Powerful but time-intensive

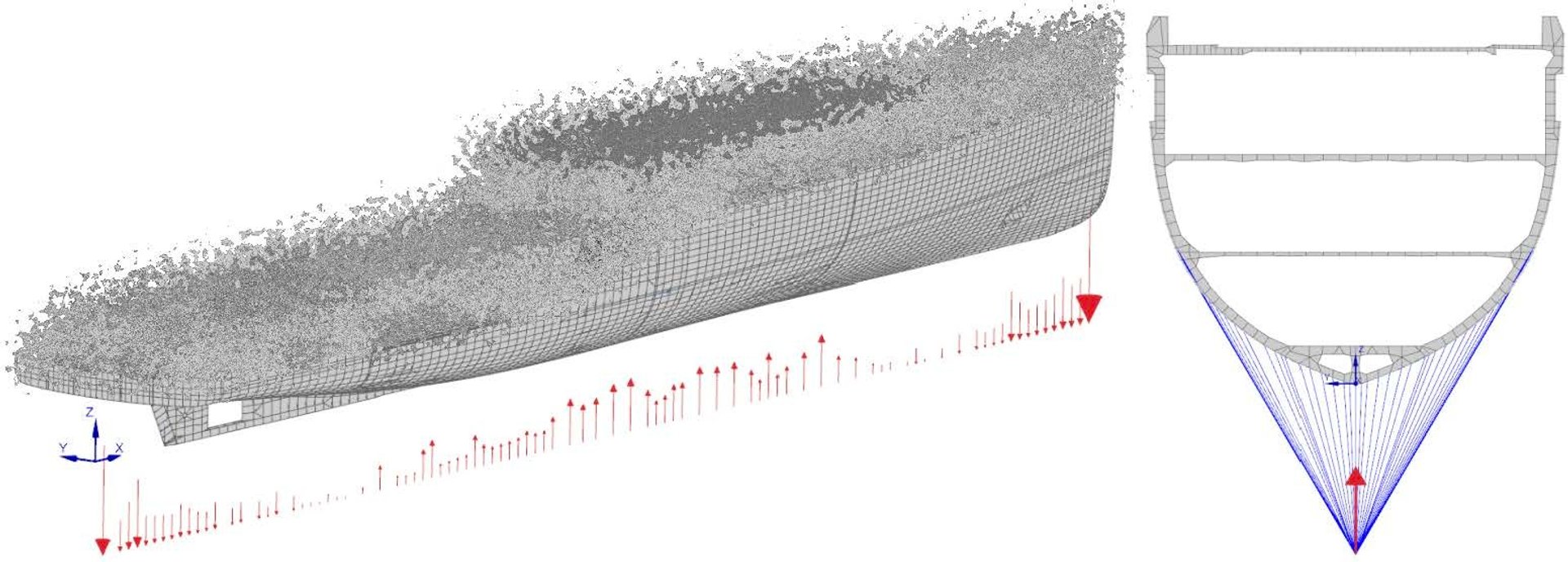

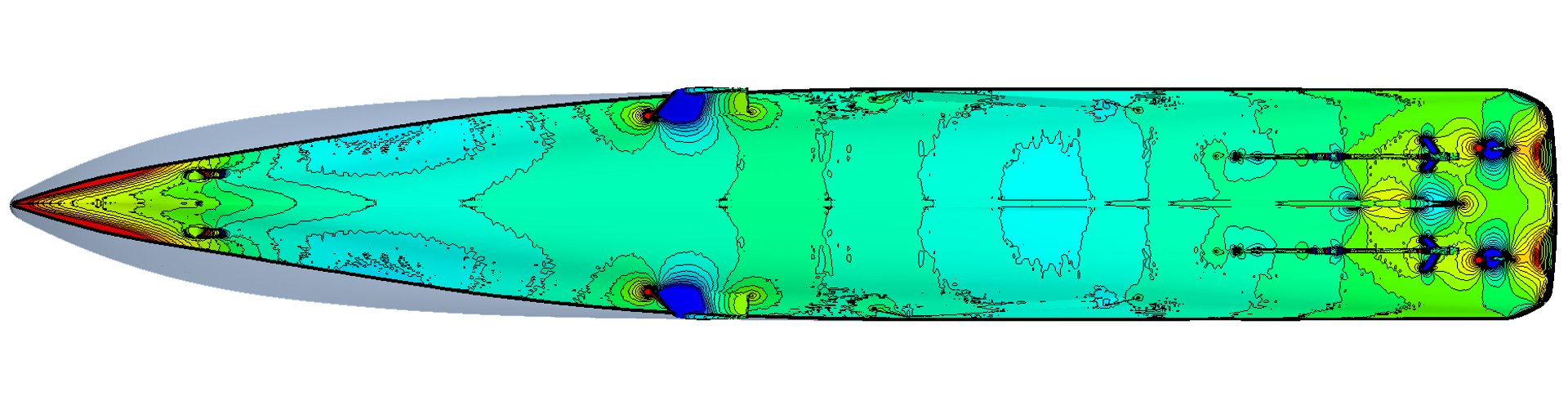

Current high-fidelity methods to analyse resistance for a multitude of ship hull variations is mainly centerd around computational fluid dynamics (CFD), which allows naval architects to simulate the fluids flow around the hull’s body. Ship resistance can reliably be determined in this way, however, their primary limitation lies in the significant time and computational resources required to obtain results. For context, a single run for a low-fidelity analysis could already take up 2 hours, which becomes impractical when a lot of hull variations need analysis in a short amount of time.

Modern AI: Instant speed, limited trust

A specific subset of modern artificial intelligence (AI), namely machine learning (ML) algorithms, have been out there for decades, but have significantly advanced in recent years as their academic and commercial adoption has grown rapidly lately. Once trained, these ML or data-driven models can deliver near-instantaneous predictions, making them an attractive alternative to traditional CFD methods. Yet, two core limitations continue to restrict their reliability and broader use:

Small datasets, big problem — Data-driven models typically need large, diverse datasets. In the maritime sector, however, data is costly to obtain, making large-scale collection impractical or sometimes even impossible.

Extrapolation, another big problem — Data-driven models struggle to make reliable predictions beyond their training domain—also known as extrapolation. A key issue in ship design, where novel hulls or conditions often lie outside available data.

Both gaps are widely recognised in academic literature and are particularly relevant for Feadship, that must deal with both these challenges to unlock the true potential of these ML algorithms for resistance prediction use cases and beyond.

Hybrid Models: bridging physics and data

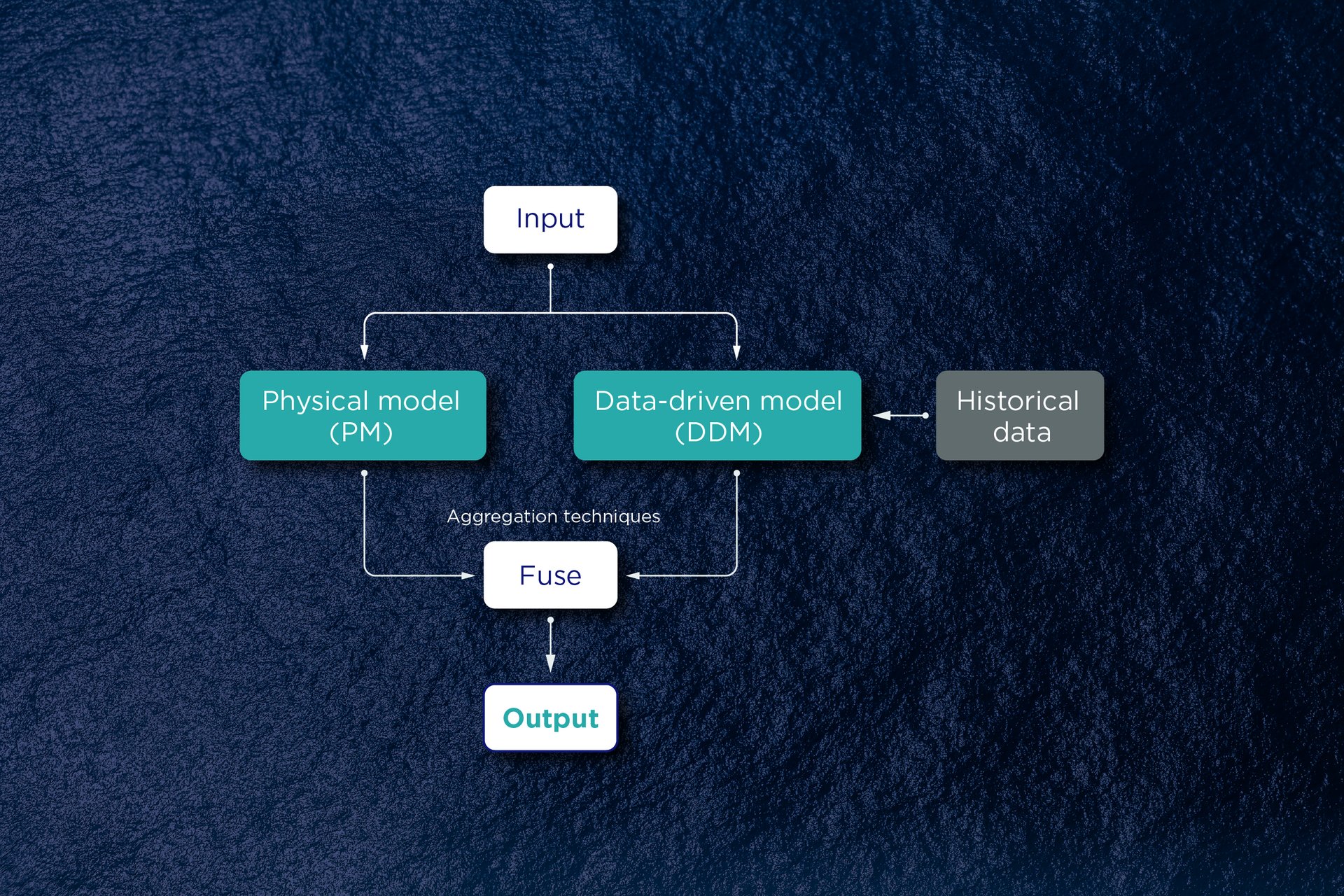

In the latest years, academics have been talking about ways to integrate physics-based relationships in machine learning algorithms to improve their prediction accuracy when dealing with either small datasets or extrapolation conditions. One solution approach, hybrid models (HMs), that aim to combine physical models (PMs) with data-driven models (DDMs). These HMs have shown promising results, and for this study efforts have been put in a new clever way of combining a widely recognised PM, the Holtrop and Mennen model, with state-of-the-art DDMs.

Feadship’s Lean Learning: powering AI with less

For nearly 15 years, Feadship has been performing high-fidelity CFD analyses on its new-build superyachts. These simulations have been carefully documented, resulting in a valuable dataset for training these machine learning models. The current training set includes 27 twin-screw superyachts, each evaluated across multiple speeds and draughts—amounting to a total of 220 CFD datapoints.

While this may seem extensive by maritime standards, it's modest in the context of data-driven modeling. Typical machine learning models require datasets on the order of 10⁴ to 10⁶ examples to perform reliably. In contrast, our dataset is in the range of 10²—meaning it would need to be at least 100 times larger to support reliable predictions. As this data is not available—just like in many other maritime use cases— it underscores the value of hybrid approaches that embed physical insights into data-driven learning.

The optimisation of these data-driven models continues, but in parallel, Feadship is already exploring ways to augment its datasets—using synthetic variations to enrich the data and increase its informational value. Whether such augmentations translate into better model performance is still to be validated, but they represent a highly promising direction worth exploring.

Correcting physics, not replacing it

Rather than predicting CFD resistance values directly—as is typically done in purely data-driven models (DDMs)—a more effective approach emerged: letting the DDM learn to apply corrections to the output of a physics-based model (PM). Traditionally, such corrections rely on the naval architect’s expertise—now, they are guided by data.

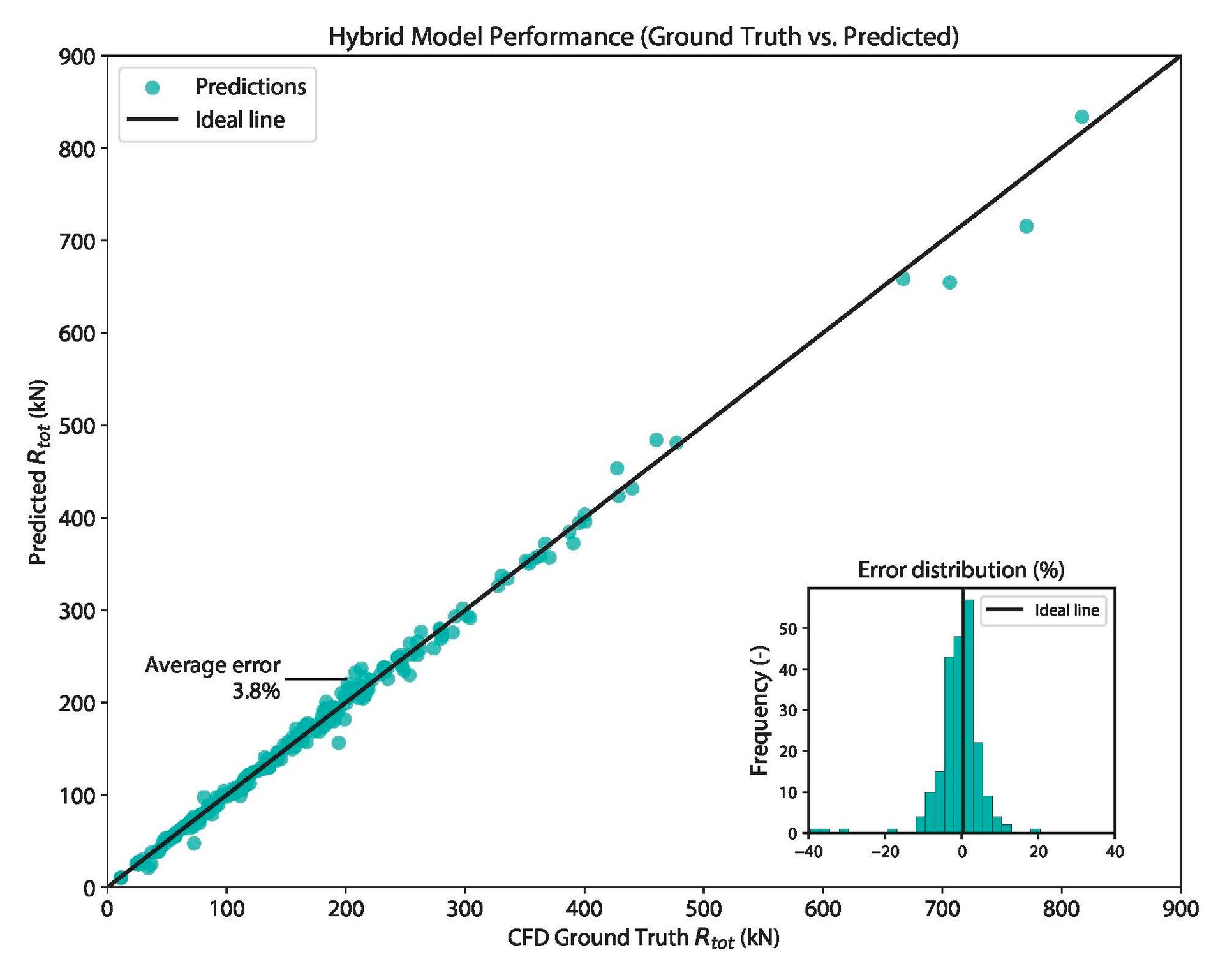

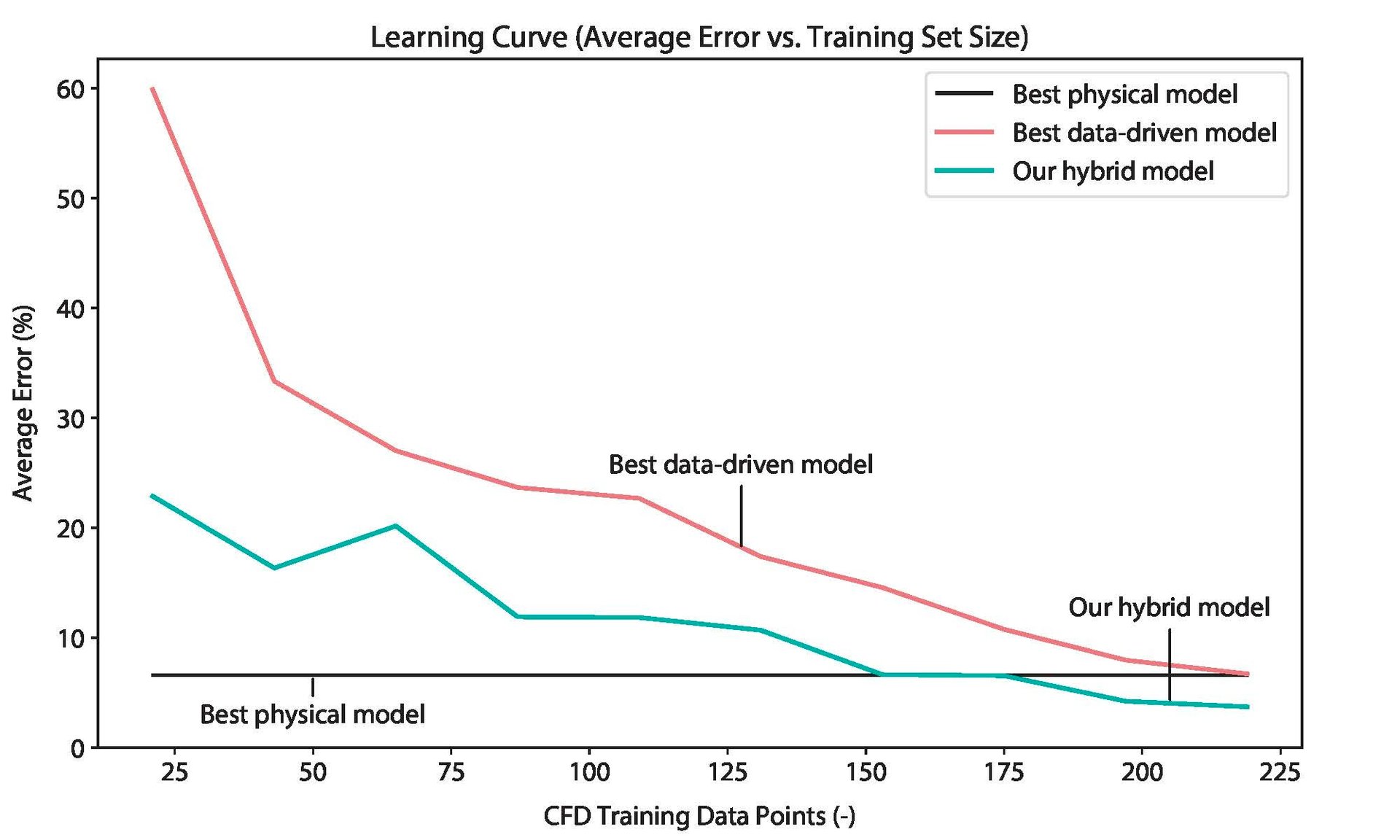

This hybrid philosophy proved remarkably successful. In our study, it achieved an average prediction error of just 3.8%, outperforming all other models tested. In practical terms, what once required hours of CFD simulation can now be achieved in seconds. A scatter plot of all 27 twin-screwed superyachts shows the predictions hugging the ideal diagonal—tight, consistent, and impressively accurate.

But the real breakthrough came in data efficiency, as can be seen in the figure above. Here, the average error across all models is evaluated step by step as CFD data is gradually added to the training sets. The hybrid model outperformed the rest, achieving equal or better results with significantly less data, making AI practical in a sector where data is costly to obtain.

The complete master thesis, including detailed test results and conclusions on for example extrapolation, can be found attached above.